By Bogdan Løw-Hansen, Joachim Wallisch, Markus Lindner, Michael Cheung and Nicolas Müller

The 1st International Workshop on Unmanned Aircraft Icing took place in Trondheim on 29th-30th of November. The purpose of the workshop was to gather different stakeholders interested in unmanned aerial vehicle (UAV) icing, including – scientists, engineers, manufacturers, investors, operators, and authorities – and learn what other stakeholders are working on and where potential collaborations can be found.

Keynote presentations

The opening talk, given by Richard Hann, highlighted the significant growth of UAVs in the current commercial and defense markets, as well as the limitations that hinder even faster growth, one of them being the atmospheric icing.

In the first keynote speech, Kim Sørensen – CEO of UBIQ Aerospace – presented the commercial opportunities related to the UAV icing challenge. Since the current solution is to ground the UAVs if there is a potential for icing, and icing conditions are likely to occur in the range of 19 to 78 days a year in the US, there is a large potential market for ice protection systems (IPS), especially light-weight and energy efficient IPS that do not reduce the operational capabilities of the UAVs.

On the second day, Professor Peter Webley from the University of Fairbanks of Alaska highlighted the challenges of operating a UAV in the Arctic. An important takeaway from the presentation is that it is not sufficient to only protect the aircraft, as the other parts of the system, like the payload, the communication links, and the pilots on the ground are highly affected by cold weather and icing as well. Therefore, a holistic view on the operations is required to ensure safe operation of UAVs in cold climates.

Research topics

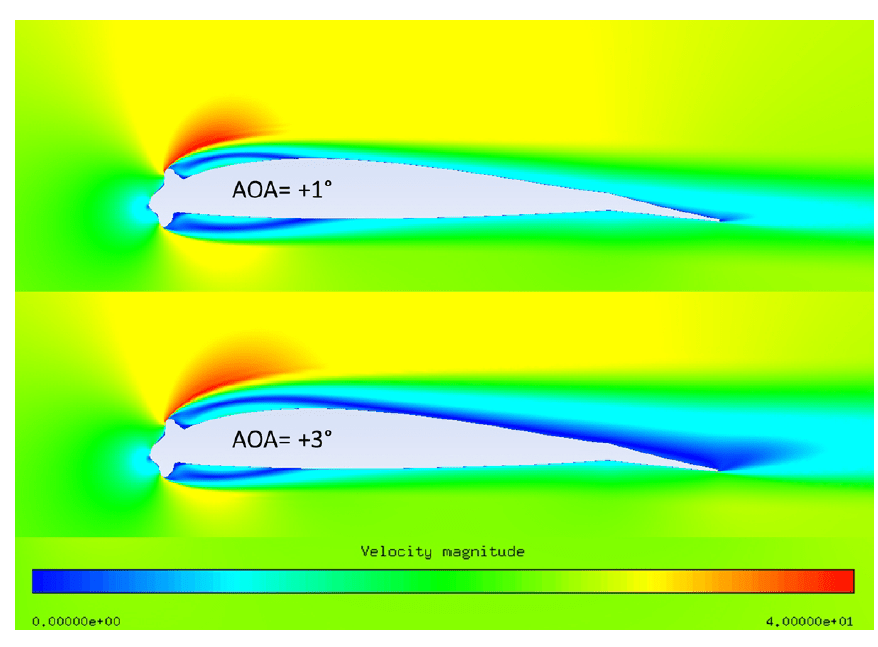

Even though UAV icing might seem like a very narrow field, based on the topics presented at the workshop, it is clear that it is a challenge that has engaged a multidisciplinary effort towards a solution. The UAV icing topic has attracted several specialists from the UAV industry, research institutions, and academia that work on solutions to enable UAV operations in icing conditions. The research presented during the workshop can be categorized into the following groups:

- Meteorology analysis and prediction of icing conditions

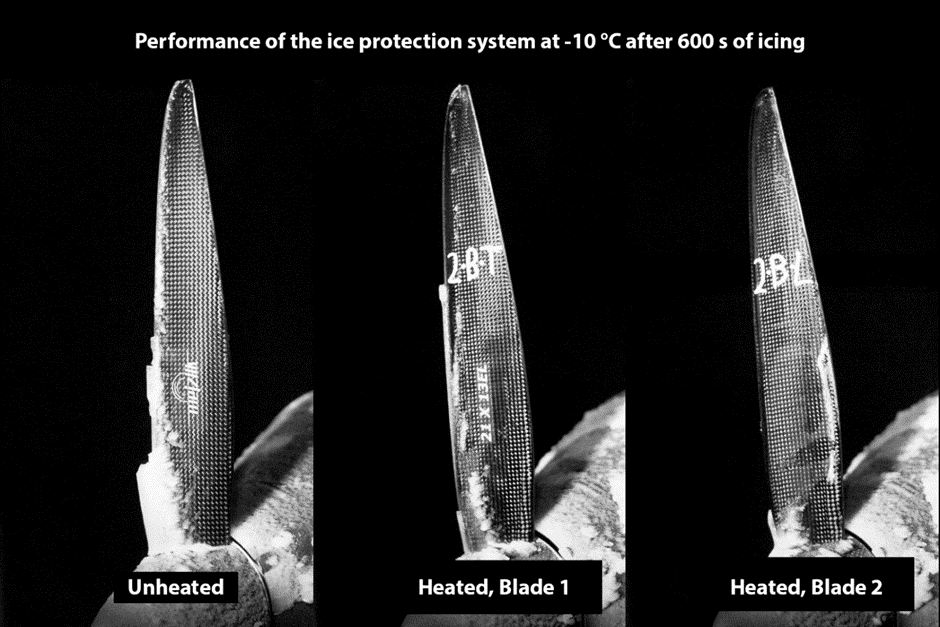

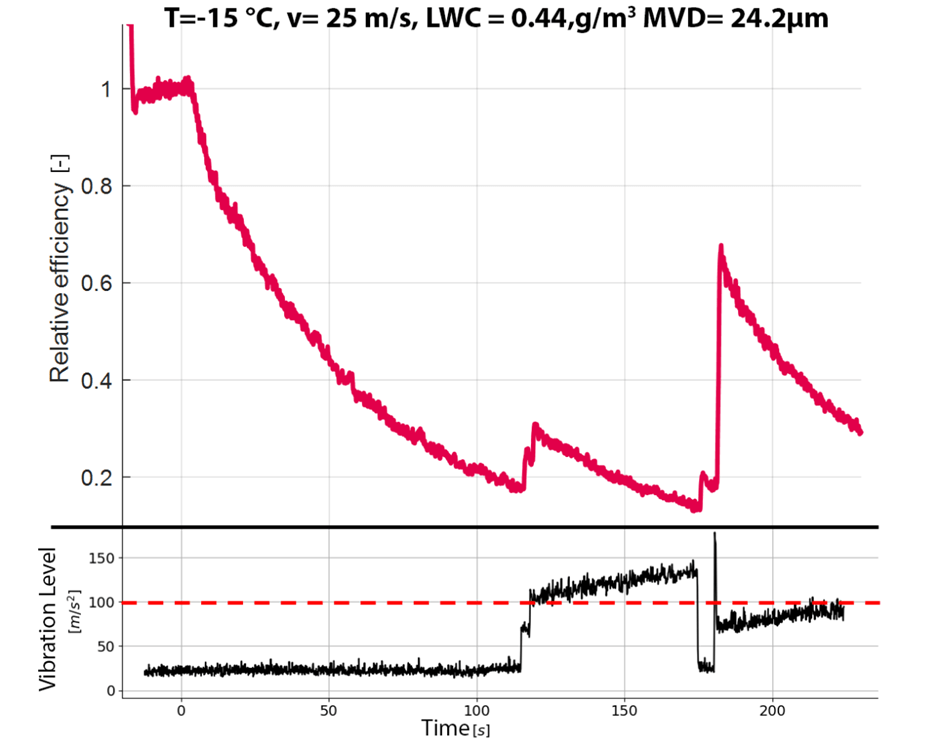

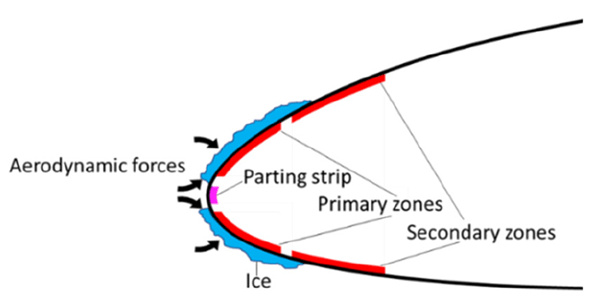

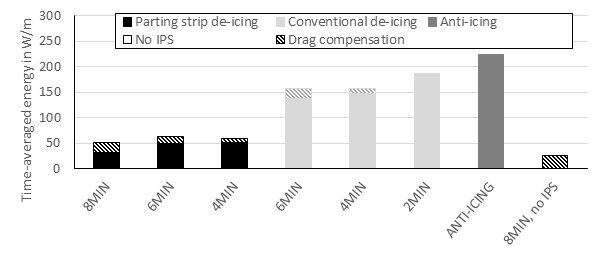

- Efficiency optimization of heat-based ice protection systems

- Efficient and lightweight ice detection sensors and methods for small UAVs

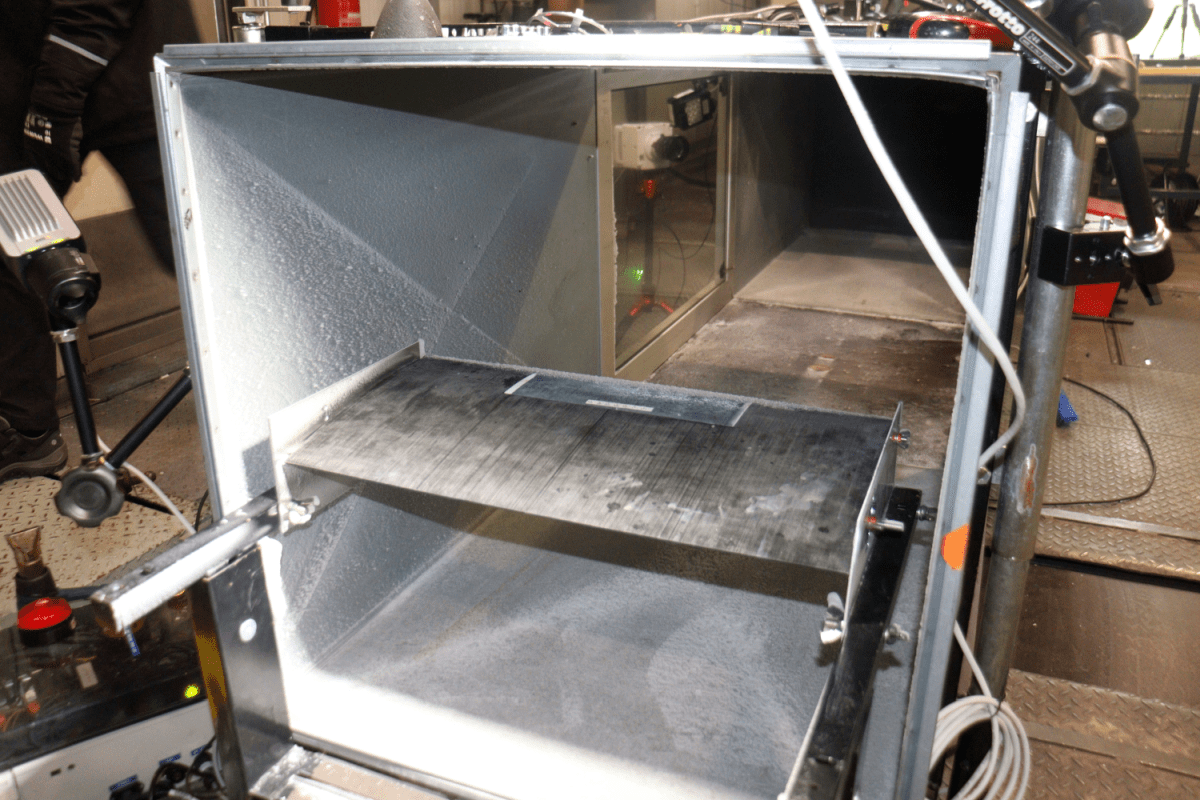

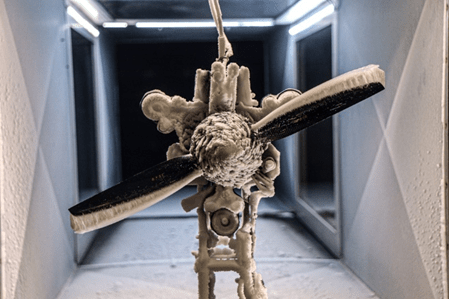

- Development of testing facilities for atmospheric icing conditions

- Research on icephobic materials and coatings

- Regulations and certification of systems for unmanned flight in icing conditions

Highlights

Many interesting facts were presented during the two-day workshop; some of the most interesting highlights are mentioned below.

Today, UAV operations are severely limited by icing. As Kim Sørensen quoted in his keynote, the current solution to UAV icing is to not fly in icing conditions:

Standard procedures for UAS operations: avoid icing at all costs. Ground the aircraft in the event of potential icing. – Boeing Insitu

Another important finding was that the main challenge of developing a viable IPS for small UAVs is to make it efficient. The current solutions require large amounts of power and are therefore highly limited by the low battery capacity of small UAVs.

Finally on the point of frequency and severity of icing conditions, VTT (Technical Research Centre of Finland), has performed a high-resolution meteorological analysis of atmospheric icing conditions in the altitude 0-1000 m, relevant for small UAVs. The results indicate that severe icing conditions will on average occur 12.8% or 47 full days per year in the region of northern Europe.

Concluding remarks

Based on the feedback, the 1st International Workshop on Unmanned Aircraft Icing was a success. The shared interest and different backgrounds of the presenters created good opportunities to find synergies and build new connections. Several social events were organized to accompany the workshop, including an informal icebreaker event held the evening before the workshop, lunch and dinner served at Scandic Nidelven Hotel, as well as a visit to a bar, which all provided an excellent opportunity to socialize.

The 2nd International Workshop on Unmanned Aircraft Icing is planned to take place in 2024. Subscribe to our newsletter to stay updated about the research done at NTNU UAV Icing Lab and the upcoming events. More information will follow on: www.uavicingworkshop.com.