** NEW PUBLICATION ** Operating drones in cold weather causes multiple challenges. Atmospheric in-cloud icing is one of them. Aircraft are often grounded during potential icing conditions because of significant performance degradation caused by ice accretion.

Ice protection systems (IPS) are one way to mitigate icing-induced performance degradations and to open the atmospheric flight envelope. However, IPS do not necessarily prevent performance degradations completely. For this study, we looked at potential performance degradations that can occur even when operating an electrothermal de-icing system on a UAV wing. Electrothermal describes that the aircraft skin is heated using electrical energy. De-icing systems allow some ice accretion before removing the ice, contrary to anti-icing systems that prevent any ice accretion.

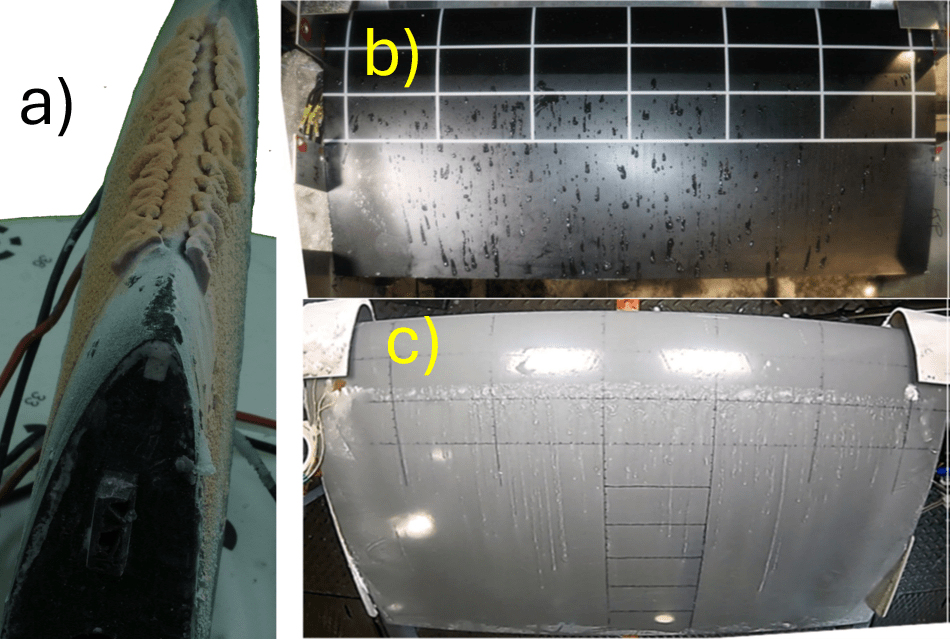

Setup – Two common types of ice accretion with a thermal de-icing system are intercycle and runback icing. Intercycle ice is the accretion that grows before the system is activated to remove the ice. An example of an intercycle ice shape after four minutes is shown below. Runback ice typically grows downstream of the heated areas. When the wing is heated, some of the meltwater will flow downstream and re-freeze in unheated areas. Runback ice can occur as dispersed spots of ice or as spanwise ice ridges.

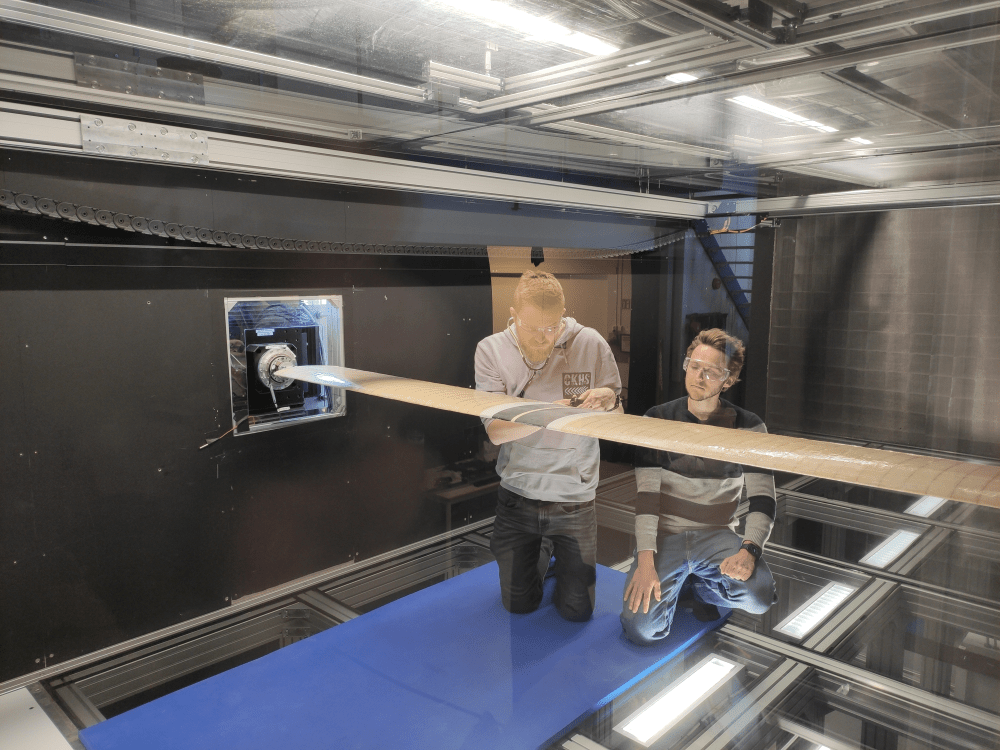

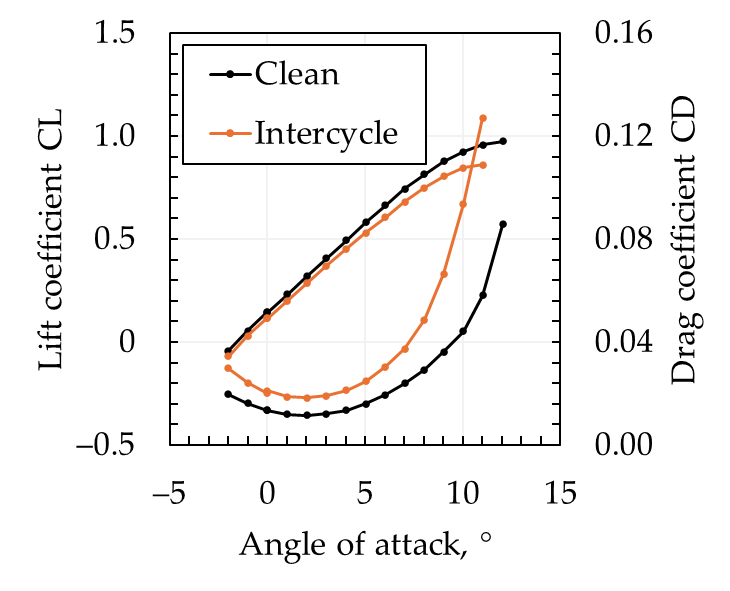

Our study investigated the changes in lift coefficient, drag coefficient, and stall angle caused by ice accretions. Experimental wind tunnel tests and numerical simulations were conducted. The wind tunnel tests were performed at the low-speed wind tunnel at NTNU. An RG-15 wing with a chord length of 0.3 m and 2.65 m span was tested at 10 m/s. Numerical simulations were conducted with Ansys FENSAP-ICE, a state-of-the-art icing simulation tool.

Results – The intercycle ice shape results in a degraded aerodynamic performance compared to the clean wing. At the realistic cruise angle of attack of 4°, the drag is increased by 58%, and the lift coefficient is reduced by 9%. This means that the aircraft would have to increase its thrust by 58% to continue its flight when flying with the intercycle ice shape compared to a clean aircraft.

The aerodynamic influence of runback ice depends significantly on the type of ice that grows. Dispersed runback ice spots reduce the lift coefficient by 2% and increase the drag coefficient by 32% compared to the clean wing at 4° angle of attack. A spanwise ice ridge reduces the aerodynamic performance more significantly. The drag coefficient at 4° angle of attack is increased by 177%, while the lift coefficient is 16% lower than in the clean case. If the UAV is intended to continue its flight in icing conditions, it would need almost three times as much thrust with the spanwise ice ridge than without. This is particularly significant because the ice ridge will likely grow in an unprotected area. Hence, the only way to remove the spanwise ice ridge would be to fly into areas with a temperature above freezing long enough to melt the ice.

Summary – Knowing the performance degradation in icing conditions is important for manufacturers and operators of UAVs and IPS. Because drones do not have much electric energy available, energy efficiency is key. This study showed that:

- Spanwise ice ridges must be prevented because of the large drag increase and because they grow in unprotected areas.

- Intercycle ice and runback ice cause non-negligible drag increases and must be considered when calculating the required energy of a thermal de-icing system.

Because runback ice grows in unprotected areas, removing it is difficult. Hence, avoidance strategies must be developed instead. Strategies to reduce the amount of runback ice include special coatings, less frequent de-icing, and adjusted heating layouts and sequences.

Text: Joachim Wallisch

Reference: Wallisch, J., Lindner, M., Petersen, Ø.W., Neunaber, I., Bracchi, T., Hearst, R.J., Hann, R. (2024). UAV Icing: Aerodynamic Degradation Caused by Intercycle and Runback Ice Shapes on an RG-15 Airfoil. Drones, 8(12), 775. doi.org/10.3390/drones8120775